-

-

-

Technology Innovation

-

Party Work

-

Talent Center

-

-

-

Technology Innovation

-

Party Work

-

Talent Center

Opening up and Innovation

DEVELOPMENT INNOVATION

Key Technologies and Applications for the Efficient Gradient Utilization of Typical Low Grade Vanadium Titano-Magnetite Tailings in Chengde

Mineral resources are an irreplaceable material basis for Chinas sustainable economic and social development. Currently, China is still under a rapid development stage of industrialization and urbanization, when rigid demands for resources continue to stay at a high level. However, China is stuck in poor resource endowment and resource shortages and thus increasingly reliant on imports of bulk minerals, which has seriously threatened the nations economic security. In recent years, Chinas reliance on imports of iron ores has exceeded 80%, which has threatened the national strategic security and aroused wide concern among all quarters of society. In order to enhance Chinas self-supply capacity of iron ores, in recent years, the country has made every effort to develop and utilize a lot of low grade iron ore resources that are difficult to be processed, of which the ultra-poor iron ore resource is a very typical one.

Ultra-poor iron ore resources are mainly distributed in Chengde of Hebei and near its west, which are magnetite-containing basic and ultra-basic magmatic intrusion, a well-known sub-variety of Damiao type vanadium-titanium magnetite in China, with a huge ore deposit, a proven reserve of 7.825 billion tons and a prospective reserve of over 10 billion tons in Chengde alone. In this type of ore, other than iron resource, it also has other valuable components such as phosphorus, copper and titanium for comprehensive utilization. This type of resource is mainly characterized by many valuable components, but an extremely low grade. In the ores, the TFe is 10-20%, of which the content of mFe is around 5% only, far lower than the industrial grade developed and utilized currently (TFe>25%, mFe>20%), the content of associated Cu is around 0.03% only, the content of P2O5 is around 2%, with a much bigger gap from the conventional beneficiations industrial grade (in the open pit mining, the content of Cu in copper sulphide ore >0.4%, the content of P2O5 in phosphorus ore >10-12%). In the process of beneficiation, a high concentration ratio is required in order to acquire qualified concentrates. Therefore, for such low grade ores, how to realize an economical and efficient recovery of valuable components is the main bottleneck for the comprehensive development and utilization of ultra-poor iron ores in Chengde. Currently in most mines, only iron resource is recovered. In some mines, phosphorus resource is recovered with a high cost and a low recovery rate. Basically, the associated low grade copper resource has not been recovered, resulting in a high waste of resources.

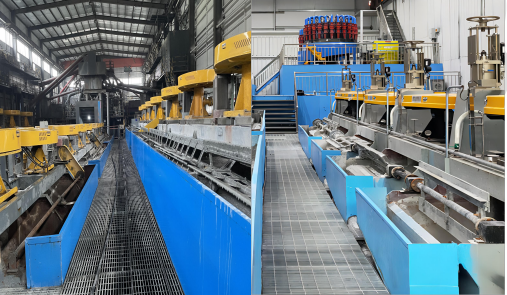

In order to efficiently utilize ultra-poor iron ore resource, save energy and reduce consumption, and advance the progress of developing technology for low grade ore deposits and associated resources in China, Chengde Baotong Mining Co., Ltd., Beijing Huaxia Jianlong Mining Science&Technology Co., Ltd., and Beijing BGRIMM Technology Co., Ltd. carried out systematic process mineralogy researches on ultra-poor iron ore resource, and technical researches on such areas as flotation recovery of copper and phosphorus minerals and efficient production of aggregates. Through flexible, repeated and full application of the nature of ores, they have formed low-cost comprehensive recovery technology with a high concentration ratio characterized by rough grinding recovery in the main process and multi-point removal of gangue minerals and developed a technological process of magnetic discarding tailings in iron separation - re-grinding and separation of copper and sulfur blend - high-concentration coarse particles of floating phosphorus - high-shear fine particles of floating phosphorus - production of aggregates with gangue and served the purposes of improving quality and efficiency and lowering the cost. Meanwhile, they have set a good example for the comprehensive utilization of ultra-poor iron ores in other mines in Chengde, generated huge economic and social benefits, protected the ecological environment of mines and strengthened the sustainability of local economy.

Project achievements have been applied in Chengde Baotong Mining and spread to surrounding mines such as Chengde Baotong Mining, Luanping Weiyuan Mining and Chengde Zonghuan Mining, achieving significant economic, social and environmental benefits.

In 2022, application was submitted to the China Nonferrous Metals Industry Association for an award for this project. The evaluation committee believed that its overall technology had reached the internationally leading level.

previous page

previous page

Copyright Beijing Huaxia Jianlong Mining Technology Co., Ltd

official account